128 – Chasewater Railway Museum Bits & Pieces

From Chasewater News April 1990

More Sid Browne Memories – Pete Aldridge

Sid Browne worked on the railways for nearly fifty years and had many anecdotes recalling his long experience. Here is another tale, as remembered by his grandson.

After working at Brownhills for some time, Sid was promoted and transferred to Monument Lane in Birmingham. This presented quite a problem, as Sid still lived in Brownhills. Sid had to travel by push bike to New Street each morning, and back again at night.

One winter’s morning, with the roads covered in snow and a force eight gale blowing, Sid set off for work. Unfortunately, he arrived just four minutes late. He hurried down onto the platform to catch the train to Monument Lane, confident that the Inspector would have held the train long enough for Sid to catch it.

The platform, however, was empty except for the Inspector, Mr. Smith.

“You’re late!” he shouted “And you’ve just lost a day’s pay”

Very angry, Sid returned home.

The following spring, Sid was guard on an evening train from Coventry to New Street. The train arrived at Stechford, and there, on the platform was Inspector Smith. As the train was the last one of the day, Smith wanted to catch a lift back to Monument Lane, where he could ‘book off’ for the night. Smith climbed into the brake end of the train.

“And where do you think you’re going?” asked Sid.

“Back to Monument Lane” replied Mr. Smith.

“Not on this train you’re not”

“But it’s the last train”

“That’s right, but some of us have got long memories, now get off!”

“Right!” said Mr. Smith “I’ll go and ride on the engine with the driver!”

“Oh no you won’t” said the fireman, who had come back down the train to see what the delay was. “If you even touch that engine I’ll unhook it and go ‘light engine’ toMonument Lane.”

Absolutely furious, Inspector Smith was left standing on the station with a long walk ahead of him.

Photo – An old Midland Railway Class ‘2F’ 0-6-0 nears the end of the line on the three mile long branch from Monument Lane to Harborne, Birmingham, in July, 1961. –Birmingham Post

Photo – An old Midland Railway Class ‘2F’ 0-6-0 nears the end of the line on the three mile long branch from Monument Lane to Harborne, Birmingham, in July, 1961. –Birmingham Post

There are two morals to this tale:

- It pays to have friends in high places.

- Don’t get mad, get even.

Working at Monument Lane did have its benefits. In particular, excursions could prove very lucrative, as being invariably overcrowded, children had to sit on parent’s laps all the way. Sid made sure that the doors on one coach were locked as it arrived at New Street. Once the rest of the train was full, Sid auctioned off the remaining seats to the highest bidder, earning more than a week’s pay.

Moral: A fool and his money are soon parted.

Crime does not pay, unless you avoid being caught!

129– Chasewater Railway Museum Bits & Pieces From Chasewater News August 1990 – More Sid Browne Memories by Peter Aldridge

129– Chasewater Railway Museum Bits & Pieces

From Chasewater News August 1990

More Sid Browne Memories – Pete Aldridge

Pines Express

More recollections from a local railwayman, Sid Browne.

The name ‘Pines Express’ will always be associated with the Somerset and Dorset Railway, but it is often forgotten that the famous train ran through some rather less picturesque parts of the world, for instance, Walsall!

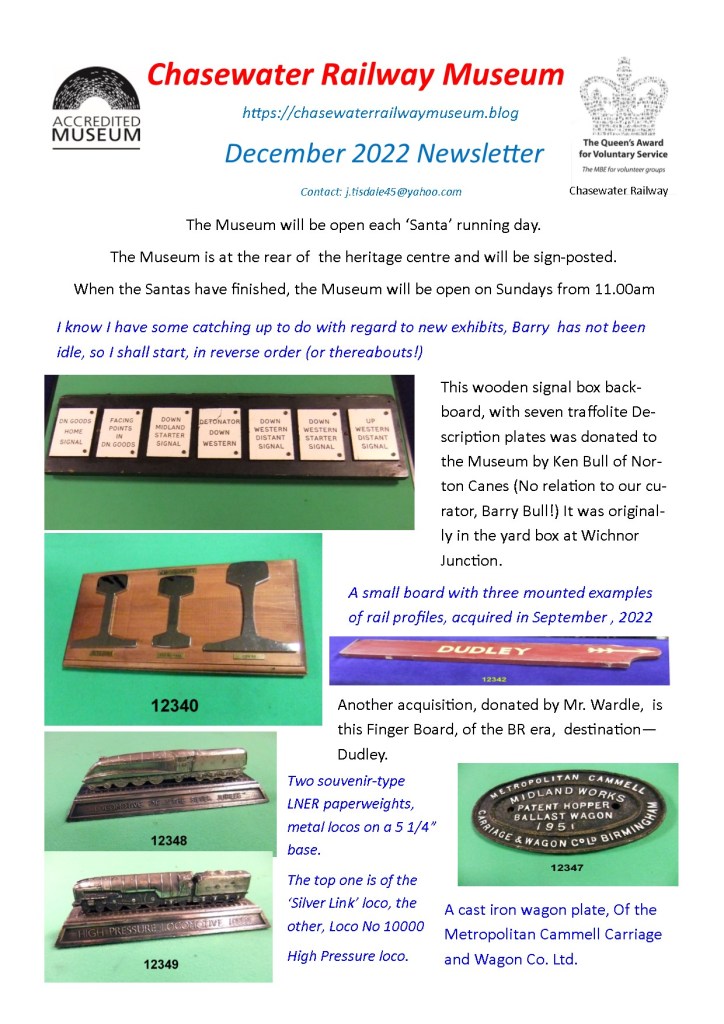

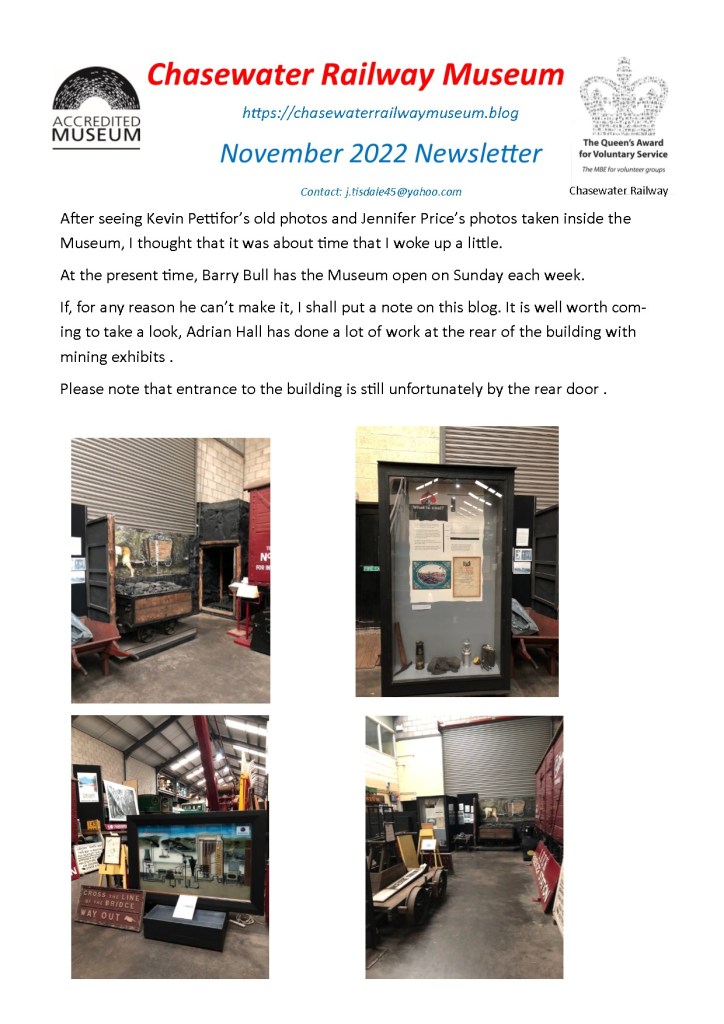

Jubilee class locomotive 45687 arriving at Walsall Station with Pines Express 1958 Jack-Haddock

Jubilee class locomotive 45687 arriving at Walsall Station with Pines Express 1958 Jack-Haddock

One overcast August day, Sid Browne stood at Walsall Station. He was to relieve the guard on the northbound ‘Pines’ and take it as far as Derby. Usually this was a cushy job, but today was to be very different. For a start, the train was late.

The train arrived ten minutes late.

‘Injectors playin’ up’ called the fireman as the engine, a Black 5, rumbled past. ‘Be lucky to reach Ryecroft at this rate’ he moaned as the engine once again disappeared in a cloud of steam. Sid got on, and the train departed. Sid saw that the train was almost empty and that the loco’s injectors were now working. Everything seemed OK. Just after Ryecroft shed, however, the injectors failed again and the train was coaxed into Aldridge.

‘Damn thing’ cursed the driver, ‘It just got past Ryecroft and then packed up’.

‘Hang on’ said Sid, ‘I’ve got an idea’ and he walked over to the ‘4F’ that was sitting in the Brownhills branch siding. A few moments later Sid walked across to the signal box ‘It’s all sorted out’ he called. The Black 5 duly came off the train and the 4F coupled on.

‘Quicker than getting an engine from Ryecroft’ said Sid, and the train set off once more.

The train arrived at Castle Bromwich Junction, half-an-hour late.

The signalman called out from his box. ‘You’ve had it mate! I’ve got no gaps onto the Derby line for hours’.

The handful of passengers complained, and the fireman from the 4F also had a gripe. ‘My shift should have finished ten minutes ago’ he complained.

After a while, the steward from the dining car came along.

‘As we’ll be here till Christmas, why don’t you have a bite to eat? I’ve got all this food left and no passengers to eat the stuff.’

Reluctantly Sid left his cheeses sandwiches and somehow managed to force himself to eat the soup, roast lamb (with a choice of vegetables) and even the apple pie and cream. Double portions of everything, of course. (Railwaymen were often prepared to make such sacrifices in the course of their work!)

So engrossed was Sid in this work that he quite failed to notice the 4F as it trundled past, heading for Bescot. Some time later, looking at empty plates, and congratulating himself on a job well done, Sid felt the train start to move. Looking out of the window he was surprised to see that not only were the signals still against them, but they had no loco on the train. Sid ran to the brake end and screwed the handbrake on. The train stopped, inches from the trap point protecting the main line. Obviously the vacuum brakes had gradually leaked off after the engine had uncoupled. The signalman returned to the train.

‘Your driver was fed up’ he explained ‘and as we’re having an engine off Saltley, they said they’d go. They said they’d told you all about it.’

‘Well’ said Sid ‘we’re well and truly in it now. The train’s fouling the crossover. The Saltley engine will have to go round the triangle and come up behind. Then he can pull us back clear of the crossover, run round, and get on the front.’

‘Can’t do that’ exclaimed the signalman, ‘I’ve got trains queuing for miles as it is. I’ll have to get your 4F back.’

The signalman hurried across to the box and got on the phone to get the 4F sent back.

The replacement engine arrived from Saltley, but could not get onto the train as it was blocking the points. The train was now nearly three hours late.

‘Disgraceful’ complained the passengers.

Eventually the 4F returned. The loco crew were not amused!

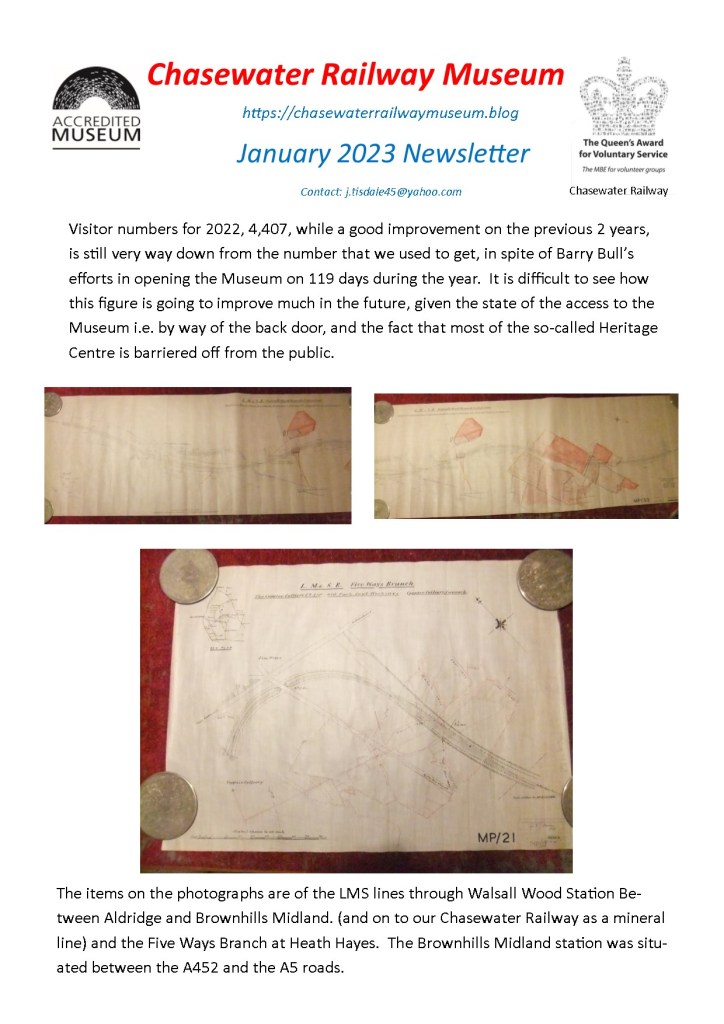

An ordinary locomotive celebrated by its unique number, seen at Stockport View SE,LMS 4F 0-6-0 No. 44444 is shunting just south of Stockport (Edgeley) station, which was on the main ex-London & North Western line from Manchester (London Road) to Crewe, also Macclesfield and Stoke-on-Trent, also Buxton. No other British Rail locomotive had a number with five identical digits.

An ordinary locomotive celebrated by its unique number, seen at Stockport View SE,LMS 4F 0-6-0 No. 44444 is shunting just south of Stockport (Edgeley) station, which was on the main ex-London & North Western line from Manchester (London Road) to Crewe, also Macclesfield and Stoke-on-Trent, also Buxton. No other British Rail locomotive had a number with five identical digits.

Creative Commons Attribution Share-alike license 2.0 Ben Brooksbank – geograph.org.uk

‘We got to Ryecroft and then we were told to come back here,’ the driver moaned. I’d almost thought I’d get home tonight!’ he grumbled.

The 4F dragged the train back clear of the crossover and the Saltley engine coupled onto the front. The 4F returned from whence it came, and the ‘Pines’ got under way once more.

The ‘Pines’ finally made it to Derby, three hours late, and Sid got off. He had missed his booked working back to Walsall and was faced with a long wait for another train.

As luck would have it, he just happened to have a cheese sandwich to keep him going till he got home to his dinner!

Jubilee class locomotive 45687 arriving at Walsall Station with Pines Express 1958 Jack-Haddock

Jubilee class locomotive 45687 arriving at Walsall Station with Pines Express 1958 Jack-Haddock